- Home

- News

- Products Information

- New Product Launch - PVC Compound

New Product Launch - PVC Compound

New Product Launch – PVC Compound

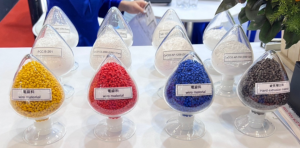

Now Available! APEX-VN PVC Compound for Diverse Industry Needs

(Learn more: Applications of PVC Compound)

Key Features of PVC Compound

- Premium Raw Materials – Made from high-purity PVC resin for enhanced stability and reliability.

- Customizable Formulations – Adjustable color, hardness, and additive ratios to meet specific needs.

- Excellent Color Retention – Uniform and stable coloring enhances product visual appeal.

- Weather & Chemical Resistance – Suitable for outdoor products, medical devices, and construction materials.

- Eco-Friendly & Safe – Complies with RoHS 2.0 and REACH standards for safety and sustainability.

- Consistent Quality & Supply – Each batch undergoes strict testing to ensure product consistency.

PVC Compound Categories

APEX-VN offers a diverse range of PVC Compound formulations, ideal for injection molding, extrusion, wire & cable, and medical industries. Our products feature high stability, excellent processability, and eco-friendly properties, with customizable options for color, hardness, and mechanical strength.

Medical-Grade Plastic Compounds

Featuring high transparency and elasticity, ensuring stable quality and precise production control for medical devices.

PVC Compound for Wire and Cable

Compliant with heavy metal-free standards, offering adjustable hardness and color, making them suitable for various industries.

.png)

Rigid Compounds for Extrusion

Exhibiting excellent formability, ideal for various industrial extrusion applications, with customizable formulations to meet specific requirements.

.png)

Flexible Compounds for Extrusion

Combining flexibility and durability, widely applied in both consumer and industrial products.

.png)

Rigid Compounds for Injection

Providing high mechanical strength, temperature resistance, and impact resistance, suitable for high-strength and high-precision products.

.png)

Flexible Compounds for Injection

Flexible and elastic, suitable for footwear, transportation facilities, and daily necessities.

Applications of PVC Compound

With outstanding physical and chemical properties, PVC Compound plays a crucial role in multiple industries, including Medical Industry, Wire & Cable, Construction Materials, Transportation, and Consumer Electronics.

.png)

Medical-Grade Plastic Compounds

Applications: Catheters, breathing tubes, medical tubing

Features: High transparency, non-toxic, odor-free, meets medical standards

(Learn more: Medical-Grade Plastic Compounds)

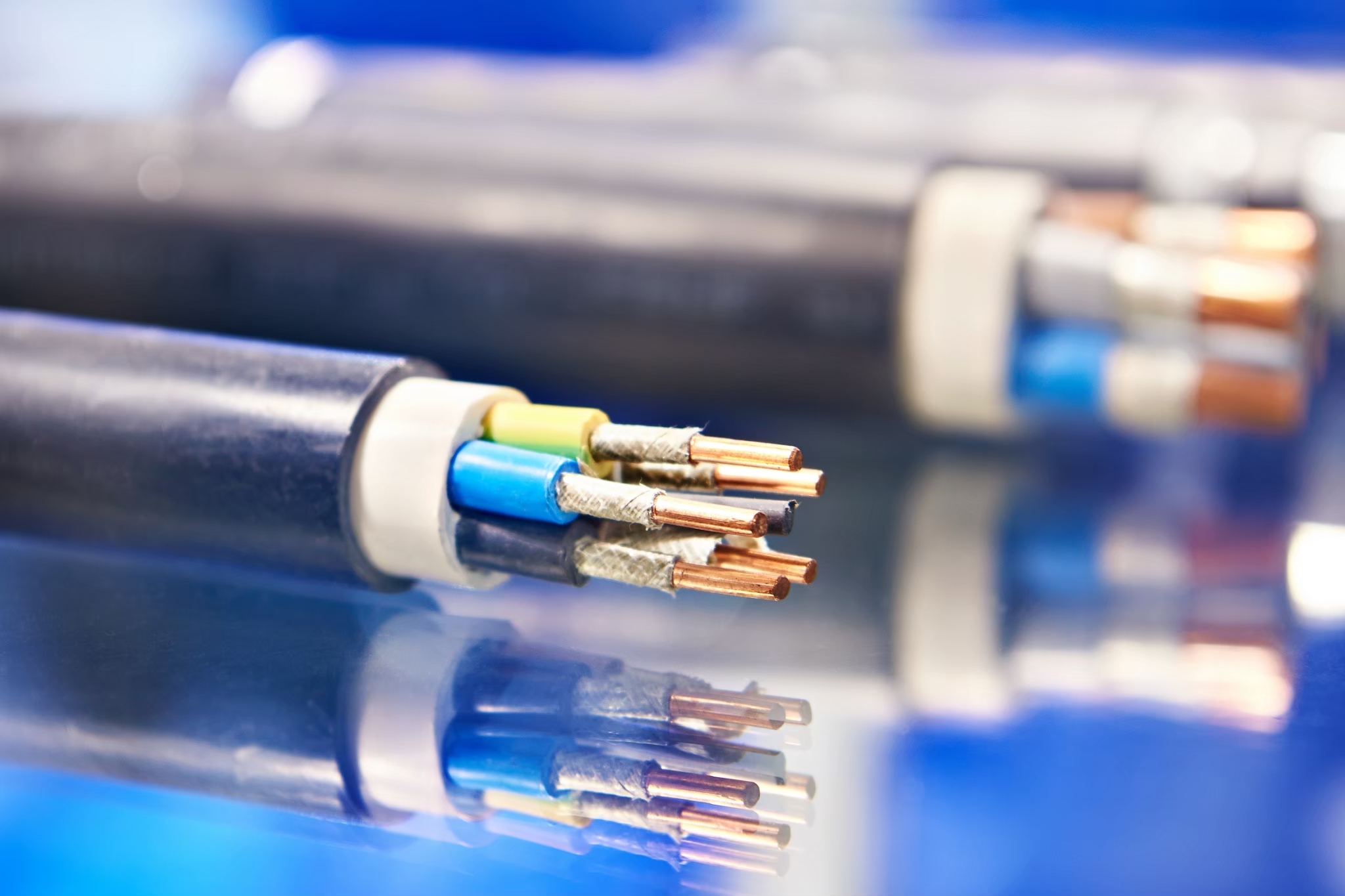

PVC Compound for Wire and Cable

Applications: Insulation layers, outer sheaths, network cables

Features: Excellent weather resistance, heat resistance, high voltage durability

(Learn more:PVC Compound for Wire and Cable)

Rigid Compounds for Extrusion

Applications: IC transparent tubes, corrugated wire tubes, window frames

Features: High rigidity, strong weather resistance, stable molding

(Learn more: Rigid Compounds for Extrusion)

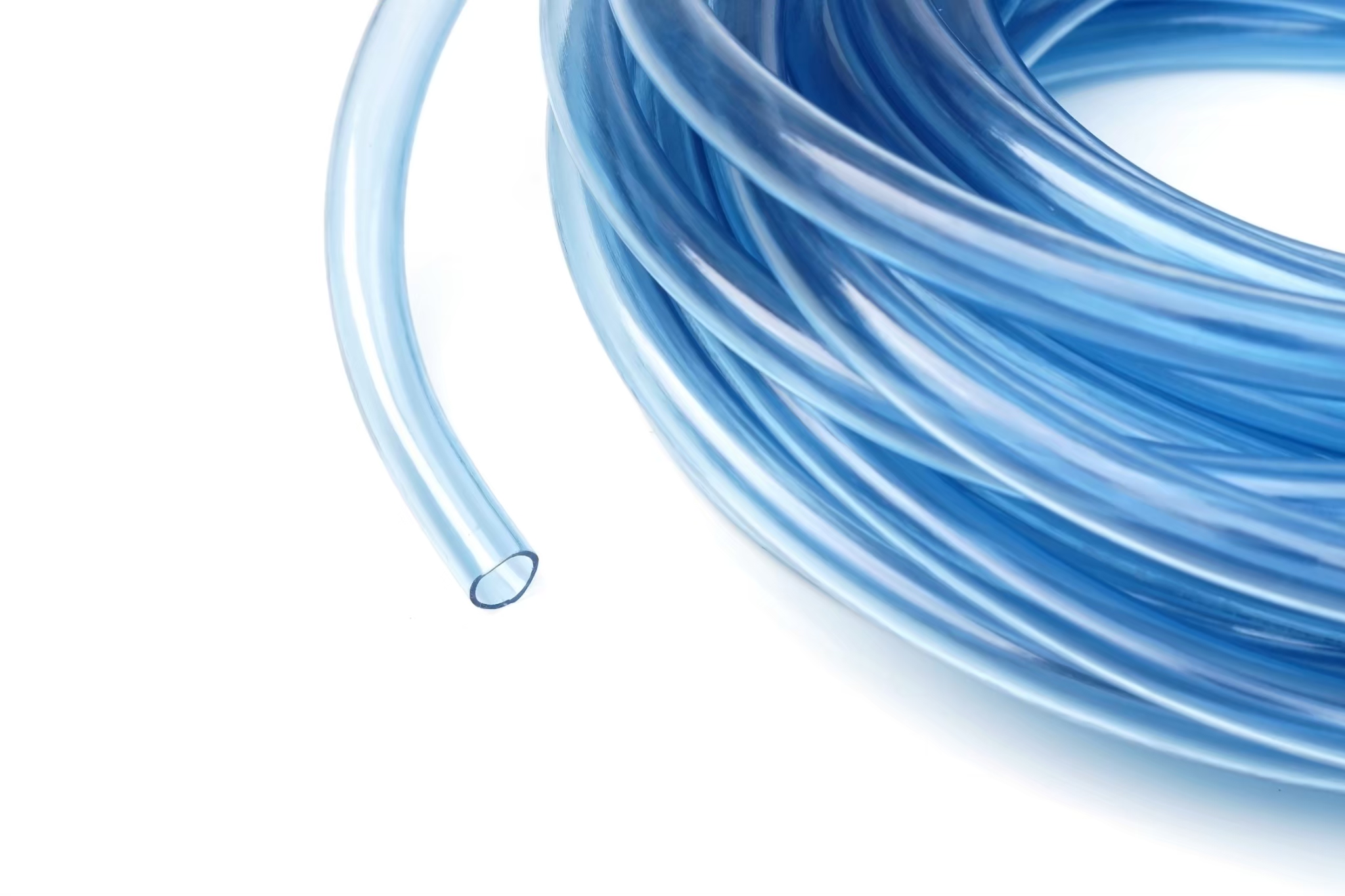

Flexible Compounds for Extrusion

Applications: Transparent tubes, soft hoses, furniture trim strips

Features: Soft yet durable, resistant to deformation

(Learn more: Flexible Compounds for Extrusion)

Rigid Compounds for Injection

Applications: Electrical casings, lamp housings, blow-molded products

Features: Impact-resistant, high rigidity, easy to process

(Learn more: Rigid Compounds for Injection)

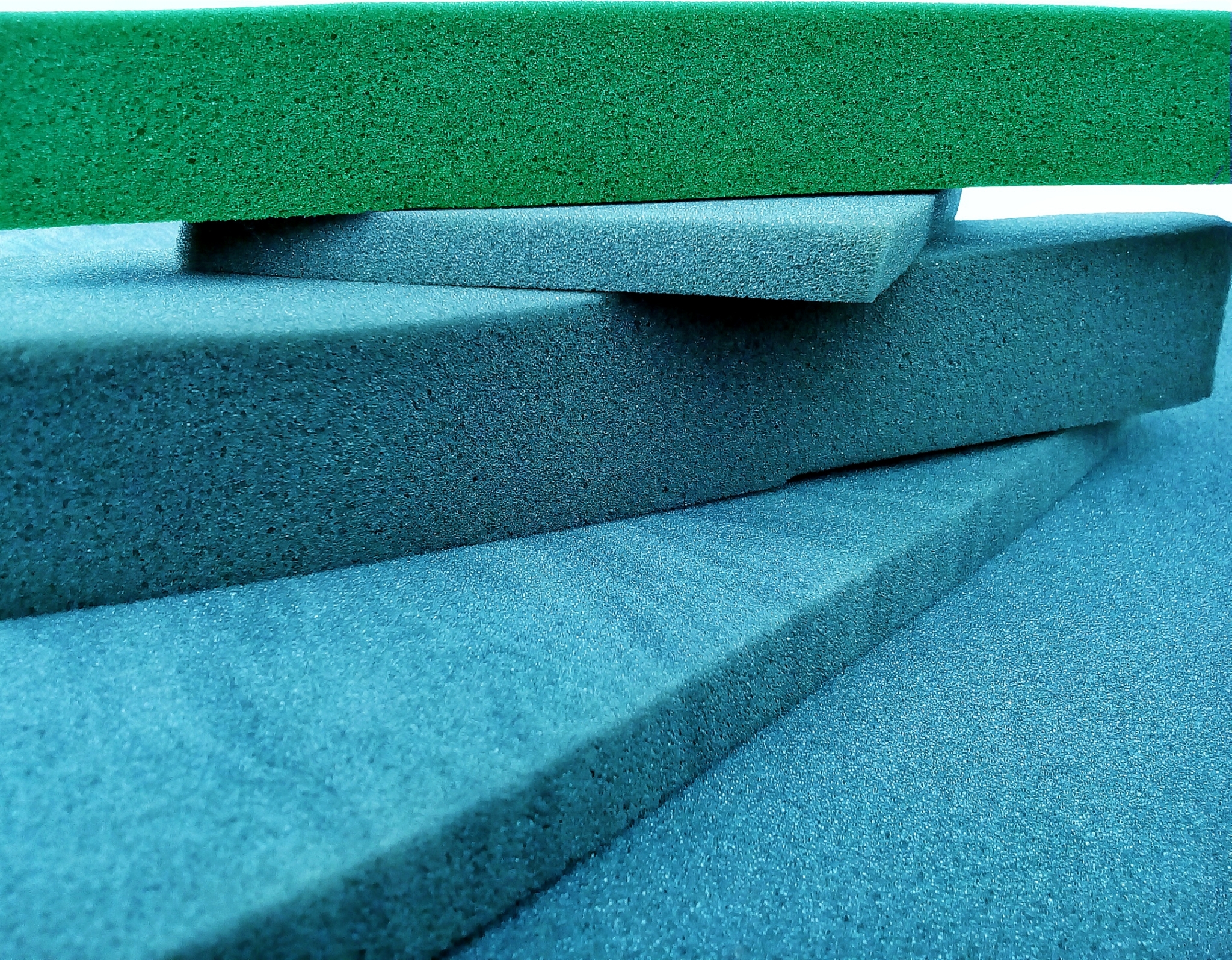

Flexible Compounds for Injection

Applications: Foam shoe materials, anti-slip mats, traffic cones

Features: Excellent elasticity, tear-resistant, shock-absorbing and durable

(Learn more: Flexible Compounds for Injection)

Advantages of APEX-VN PVC Compound

High-Quality Assurance

Strict Quality Control

Flexible Supply Options

Packaging and Logistics

Diverse Packaging Options

Custom-Printed Packaging

In-House Fleet System

Conclusion

We welcome you to contact us for samples or more details on product applications. APEX-VN remains dedicated to offering top-quality materials and professional services to support the continued success of your business.

Contact Information

Phone: +84-274-362-0911

Fax: +84-274-3620665

Email: sales@vnapex.com

ZALO : Link (Click Here)

Or scan the QR code below