APEX-VN Factory Facilities

Introduction of APEX-VN Factory Facilities

APEX-VN takes pride in its advanced manufacturing facilities, which stand as pillars within the Southeast Asian rubber and plastics industry. Our equipment belongs to the highest global standards, surpassing those in China and on par with imported units from Europe, the United States, and Japan, ensuring our ability to meet diverse customer needs.

Whether you require large-scale production of calcium carbonate powder or customized plastic masterbatches, we possess the appropriate machinery and infrastructure to accommodate various scales and requirements.

Our factory facilities are meticulously planned, integrating modern equipment and intelligent manufacturing processes. These initiatives not only contribute to cost savings and enhanced production efficiency but also ensure product quality and consistency.

APEX-VN’s Facilities

.jpg)

Mining Resources

With abundant mining resources, we ensure a stable supply of raw materials to meet the large demands of various customers. While maintaining high quality, we provide reliable and continuous delivery.

Raw Material Inventory

APEX-VN has a dedicated Limestone Lump storage area for storing limestone chunks, a crucial raw material used in the production of calcium carbonate powder. This storage area ensures the limestone is kept in optimal conditions, preserving its quality for subsequent processing in our manufacturing operations. By maintaining strict control over our raw materials, we guarantee consistent product quality from start to finish.

The crushing station and the washing station

The crushing station is responsible for crushing large raw materials into smaller particles. The washing station, on the other hand, is used to clean and purify materials that have already been processed through the crushing station.

Raw Materials Storage equipment

APEX-VN stores minerals like dolomite and limestone in well-designed facilities with proper environmental controls to maintain optimal temperature and humidity. Modern loading systems and safety measures ensure compliance with industry standards for safe production.

Automatic Metering System

Automatic Metering System is a system used to automatically measure, record, and control the flow, weight, or volume of substances or fluids to ensure accurate material input and product quality.

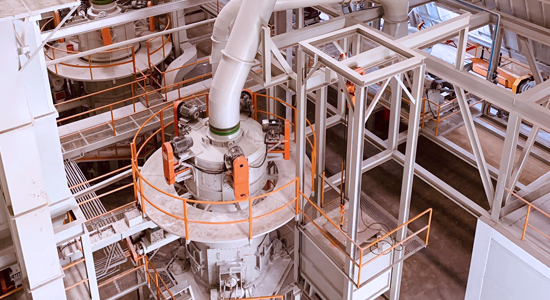

Vertical milling machine

Vertical mills are crucial for maintaining the high quality of calcium carbonate powder at APEX-VN. These mills facilitate continuous processing, reducing production time and costs while ensuring high-quality and efficient powder production.

Twin Screws Extruder

Phase one includes four twin-screw extruders, with phase two expanding to ten twin-screw extruders and four 10,000-horsepower kneaders. Each twin-screw machine at APEX-VN produces 1.5 tons per hour, while each kneader has a capacity of 800 kilograms per hour.

Human Machine Interface

Our HMI streamlines control of Inorganic Powder and Masterbatch manufacturing processes. This user-friendly interface empowers operators, offering intuitive control and real-time monitoring for enhanced productivity.

Semi-Finished Product Particle Inspection

The particle detection process for semi-finished products is designed to ensure they meet required quality standards. This step helps to identify and eliminate any particle contamination that could affect the integrity, performance, and safety of the final products, maintaining overall production quality.

The semi-automatic filling and packaging area

To increase packaging speed and reduce the risk of manual packaging errors.

APEX Robotic Stacking System

Accelerate finished product stacking speed to reduce stocking time and deliver goods to customers more quickly.

Finished Product Particle Inspection

Particle detection ensures the final quality and safety of finished products by identifying any foreign objects. Masterbatch products undergo this process to meet industry standards and customer specifications.

Quality Control and Precision Laboratory

Continuing the quality inspection system from our parent factory in Taiwan, we conduct online inspections for immediate corrections.

Finished Goods Storage Area

The Finished Goods Storage Area securely stores completed products like Masterbatch and calcium carbonate powder, ensuring they are ready for shipment. Proper organization allows for efficient inventory management and quick order fulfillment.

Conclusion

In conclusion, the APEX-VN factory facilities represent a pinnacle of advanced manufacturing infrastructure within the Southeast Asian rubber and plastics industry. With state-of-the-art equipment surpassing global standards, meticulous planning, and integration of modern technologies, we ensure the highest quality, efficiency, and consistency in our production processes. From raw material inventory management to cutting-edge machinery for processing and packaging, we are committed to meeting diverse customer needs while maintaining the highest standards of safety and environmental responsibility. With our focus on continuous improvement and customer satisfaction, APEX-VN is poised to remain a leader in the industry, delivering exceptional products and services to our valued customers.